Activities

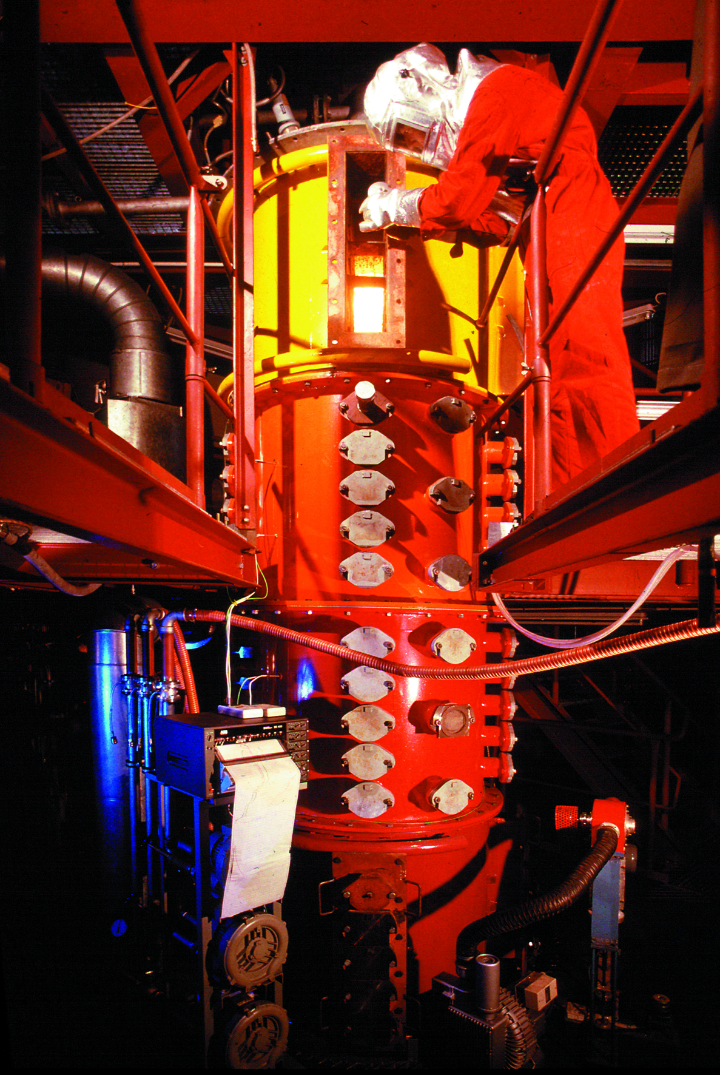

The work in the department „Firing Systems” is devoted to experimental and theoretical investigations of combustion and steam generation issues in utility boilers and industrial combustion systems. For this purpose, a variety of experimental facilities is available at IFK. Our own workshop allows to modify the facilities according to the needs of each specific research project. In our laboratory, fuel and ash analyses as well as material tests can be made. In parallel, theoretical models for the description and analysis of combustion phenomena are applied. Based on the experimental results, the validation of the theoretical models and their optimization is triggered.

Beyond the activities at the laboratory and semi-industrial scale, measurements at large scale plants are planned and performed, utilizing various measurement technologies which have been successfully applied in previous campaigns at industrial sites.

- CO2-free and highly-efficient power plant concepts, e.g., oxy-fuel process, 700°C power plant, combustion of pre-dried lignite, high temperature processes (EFCC)

- Biomass and SRF co-combustion in coal-fired power plants

- Characterization of slagging and fouling and corrosion phenomena

- Experimental and theoretical investigations of pollutant formation and pollutant reduction measures in coal-fired power plants (NOx, SO2, heavy metals, fine dust)

- Investigation of operational problems in coal-fired power plants (ignition, burn-out, deposit formation, corrosion)

- Characterization and use of combustion residues (fly ash, gypsum)

- Development and application of standards for fuel and ash analysis (CEN, DIN)

Research projects

CO2-free and highly-efficient power plant concepts

Due to the increasing share of renewable energy production and the necessity to reduce CO2 emissions, fossil fuel power plants face new challenges. In consequence, the plants are forced to follow a fluctuating demand and thus need to work in part load and with more frequent shutdown. To increase the efficiency and flexibility of fossil fuel power plants the FlexIgnite project funded by BMWi (Federal ministry of Economics and Technology) aims to improve the restart and min load operation by application of electrical ignition system such as plasma torches and heated nozzles. The electrical ignition system ignites directly the primary fuel i.e. coal to start the plant, which eliminates the utilization of costly natural gas or oil for startup.

Contact persons: R. Youssefi, J. Maier

Test Facilities: KSVA

Beginning: 01.07.2016, time: 36 months

DRYLIG is an RFCS project focusing on use of pre-dried lignite for flexibility in power plants. Main scope of the project is the development of new and innovative retrofitting concepts for lignite pre-drying and pre-dried lignite co-firing. The proposed concepts are intended for existing lignite power plant (increase of flexibility, improved operational and environmental performance under low loads), hard coal plants (as start-up/co-firing fuel) and, finally, the enlargement of pre-dried lignite applications in other industrial applications. The research focus of IFK is:

- Milling and drying experiments of low quality lignite containing high moisture and ash content in IFK´s fan beater mill facility

- Small (20 kWth) and large (500 kWth) technical scale co-firing tests of pre-dried lignite & hard coal in different thermal shares to assess emission behavior, slagging and fouling, burnout and fly ash quality.

Contact persons: I. Papandreou, J. Maier

Test Facilities: Fan Beater Mill, KSVA, BTS-VR

Beginning: 01.07.2014, time: 36 months

CEMCAP is an Horizon 2020 project regarding CCS technology development for cement production. IFK’s department Firing Systems is involved in the design, testing and optimization of an oxy-fuel burner as well as in the experimental investigation of entrained flow calcination under oxy-fuel conditions. The Decentralized Energy Conversion department of the IFK is also involved in the project with investigations on the Calcium Looping process.

Contact persons: F. Carrasco, J. Maier

Test Facilities: BTS-VR, KSVA

Beginning: 01.05.2015, time: 48 months

The main objective of the EU RFCS project BiOxySorb is an experimental and techno-economic assessment of 1st and 2nd generation biomass co-combustion under both air- and oxy-fuel conditions at various co-combustion ratios in combination with flexible, low cost SOx, HCl and Hg emission control by sorbent injection. The project is administered and technically coordinated by IFK.

Contact persons: R. Spörl, J. Maier, A. Fuller

Test Facilities: KSVA, BTS-VR

Beginning: 01.07.2013, time: 36 months

In the EU FP7 research project, IFK is involved in fuel, flame and combustion characterization and investigations of high temperature gas-side corrosion, flue gas clean-up and the behavior of mercury under oxy-fuel combustion conditions.

Contact persons: M. Escoto de Tejada, J. Maier

Test Facilities: BTS-VR, KSVA

Beginning: 01.12.2011, time: 48 months

IIn this German federal research project, IFK investigates the influence of fuel composition and combustion conditions (air, oxy-fuel) on deposit and ash formation and transformation. Moreover, interactions between flue gases, deposits and heat exchanger materials are being evaluated.

Contact persons: R. Spörl, M. Paneru

Test Facilities: KSVA, BTS-VR

Beginning: 01.04.2011, time: 36 months

The project is administered and technically coordinated by IVD. Major RTD topic is influence of supercritical steam parameters and the combustion atmosphere on the new state-of-the-art evaporator and superheater materials in both conventional air and oxy-fuel firings.

Contact persons: G. Stein-Brzozowska, O. Lemp

Test Facilities: KSVA, laboratory tests, long-time expositions, field measurements in power plants

Beginning: 01.01.2007, time: 4 years

The project is administered and technically coordinated by IVD. Major RTD topics are combustion tests with different burner set-ups and validation and evaluation of burner set-ups (up to a scale of 30 MW) by using the IFK CFD combustion model AIOLOS.

Contact persons: S. Grathwohl, J. Maier

Test Facilities: KSVA, BTS-VR

Beginning: 01.07.2006, time: 3 years

The project is administered and technically coordinated by IVD. Major RTD topics are the development and demonstration of innovative approaches to the high efficient co-utilisation of low quality biomasses and Solid Recovered Fuels (SRF) produced from municipal solid waste (MSW) for electricity production and combined heat and power (CHP) usage, at competitive costs, high plant availability and advanced energy efficiency.

Contact persons: B. Schwald, A. Fuller

Test Facilities: KSVA, BTS-VR

Beginning: 01.01.2010, time: 36 months

The project aims at technologies that meet the target of at least a 90% CO2-capture rate. IVD, as one of the major RTD providers, focuses on the operation and emission formation under Oxyfuel process conditions up to a scale of 500 kW.

Contact person: J. Maier

Test Facilities: KSVA, BTS-VR

Beginning: 01.03.2004, time: 5 years

Biomass and alternative fuels

During the combustion of pre-treated biomass with its high contents of chlorine and alkali as well as heavy metals, highly corrosive conditions prevail which place high demands on the installed metal components. The research focus of IFK in this BMWi (Federal Ministry for Economics and Technology) -funded project is the characterization of different pre-treated biomass fuels as well as their evaluation with regard to ash and deposit formation on flue gas side. The DECHEMA Research Institute concentrates on the further development and optimization of suitable coating processes for the protection of the metal surfaces against high-temperature corrosion.

Contact persons: E. Miller, J. Maier

Test Facility: KSVA

Beginning: 01.06.2016, time: 30 months

The use of biomass and bio-waste in coal-fired power plants is a recognized and important way to achieve the internationally agreed targets for reducing greenhouse gases. In this project on sustainability research with German and Polish partners, methods are to be developed for the pretreatment of biomass for greenhouse gas reduction technologies, in particular for combustion processes with biomass in power generation. The use of waste biomass instead of high quality woody biomass requires pretreatment to reduce adverse effects. The stringy and fibrous nature of the biomass complicates the milling process and co-incineration in existing coal dust mills and combustion systems. Other problems such as slagging and deposits are associated with the significant level of alkali metals in the biomass ash. These limitations require the development of a pre-treatment technique that improves and standardizes the biomass quality, so that it can be used as a substitute fuel for coal.

Contact persons: A. Mack, J. Maier

Test Facilities: KSVA, BTS-VR

Beginning: 10.2016, time: 36 months

The main objective of the EU RFCS project BiOxySorb is an experimental and techno-economic assessment of 1st and 2nd generation biomass co-combustion under both air- and oxy-fuel conditions at various co-combustion ratios in combination with flexible, low cost SOx, HCl and Hg emission control by sorbent injection. The project is administered and technically coordinated by IFK.

Contact persons: R. Spörl, J. Maier, A. Fuller

Test Facilities: KSVA, BTS-VR

Beginning: 01.07.2013, time: 36 months

The focus of the project is to perform a techno-economic assessment of co-firing regionally available biomass fuels in coal-fired power plants. The project should clearly identify problems associated with co-firing at high thermal shares while also prescribing possible scenarios and to what extent biomasses can serve as substitute to coal in power plants. IFK is responsible for performing combustion tests and assessment of performance characteristics of various biomass fuels in cooperation with IET (Technical University Hamburg), who in addition to project coordination will perform detailed simulation and modeling in order to identify the best possible case scenarios for co-firing various biomasses in coal-fired power plants.

Contact persons: C. Ndibe, M. Paneru, J. Maier

Test Facilities: KSVA, BTS-VR

Beginning: 01.12.2012, time: 36 months

The BioBoost project concentrates on dry and wet residual biomass and wastes as feedstock for de-central conversion by fast pyrolysis, catalytic pyrolysis and hydrothermal carbonisation to the intermediate energy carriers’ oil, coal or slurry. IFK is performing combustion test of the energy carriers produced from these processes (Bio-Char from pyrolysis and Bio-Coal from hydrothermal carbonisation process). Investigations will focus on the combustion/co-combustion performance and emission behavior. Moreover, fly ash and deposit characteristics regarding slagging fouling and corrosion will be evaluated.

Contact persons: M. Paneru, J. Maier

Test Facilities: BTS-VR, KSVA

Beginning: 01.12.2012, time: 42 months

The SECTOR project is focussed on the further development of torrefaction-based technologies for the production of solid bioenergy carriers up to pilot-plant scale and beyond, and on supporting the market introduction of torrefaction-based bioenergy carriers as a commodity (renewable solid fuel).

IFK is coordinating the end-use performance evaluation of these torrefaction-based bioenergy carriers considering four end-use options, starting from raw biomass to heat, electricity, biofuels, bio-chemicals and/or bio-materials.

Contact persons: C. Ndibe, J. Maier

Test Facilities: KSVA, BTS-VR

Beginning: 01.12.2012, time: 36 months

The project is administered and technically coordinated by IVD. Major RTD topics are the development and demonstration of innovative approaches to the high efficient co-utilisation of low quality biomasses and Solid Recovered Fuels (SRF) produced from municipal solid waste (MSW) for electricity production and combined heat and power (CHP) usage, at competitive costs, high plant availability and advanced energy efficiency.

Contact persons: B. Schwald, A. Fuller

Test Facilities: KSVA, BTS-VR

Beginning: 01.01.2010, time: 36 months

The project is administered and technically coordinated by IVD. The DEBCO project responds to the need for further operational experience in high share biomass co-firing using different type of fuels. The project aim to demonstrate and assess, on a long term basis, the advanced and innovative co-firing techniques that are capable of achieving higher shares of biomass up to 50% more on a thermal basis.

Contact persons: B. Schwald, A. Fuller, G. Dunnu

Test Facilities: KSVA, BTS-VR

Beginning: 01.01.2008, time: 48 months

Contact persons: D. Dunnu, J. Maier

Test Facilities: DIVA/ELWIRA

Beginning: 10.2012, time: 36 months

Petroleum coke (Petcoke) is a carbon-rich solid byproduct derived from the crude oil refining process and an interesting alternative energy source due to its high heating value, low ash content and competitive price. More efficient, cleaner and climate-friendlier technologies for petcoke combustion are needed to fully exploit the potential of this residue. This project, with funding from King Abdullah University of Science and Technology (KAUST) and within the framework of the International Partnership for Carbon Neutral Combustion (IPCNC), aims at evaluating the combustion behaviour of petcoke under air and oxy-fuel conditions. For this purpose, combustion tests are performed at IFK´s 20kW electrically heated entrained flow reactor.

Contact persons: M. Escoto de Tejada, J. Maier

Test facilities: BTS-VR

Beginning: 01.07.2016, time: 12 months

Pollutant formation and reduction

The main objective of the EU RFCS project BiOxySorb is an experimental and techno-economic assessment of 1st and 2nd generation biomass co-combustion under both air- and oxy-fuel conditions at various co-combustion ratios in combination with flexible, low cost SOx, HCl and Hg emission control by sorbent injection. The project is administered and technically coordinated by IFK.

Contact persons: R. Spörl, J. Maier, A. Fuller

Test Facilities: KSVA, BTS-VR

Beginning: 01.07.2013, time: 36 months

Combustion residues

The main objective of the EU RFCS project BiOxySorb is an experimental and techno-economic assessment of 1st and 2nd generation biomass co-combustion under both air- and oxy-fuel conditions at various co-combustion ratios in combination with flexible, low cost SOx, HCl and Hg emission control by sorbent injection. The project is administered and technically coordinated by IFK.

Contact persons: R. Spörl, J. Maier, A. Fuller

Test Facilities: KSVA, BTS-VR

Beginning: 01.07.2013, time: 36 months

The project is administered and technically coordinated by IVD. The DEBCO project responds to the need for further operational experience in high share biomass co-firing using different type of fuels. The project aim to demonstrate and assess, on a long term basis, the advanced and innovative co-firing techniques that are capable of achieving higher shares of biomass up to 50% more on a thermal basis.

Contact persons: B. Schwald, A. Fuller, G. Dunnu

Test Facilities: KSVA, BTS-VR

Beginning: 01.01.2008, time: 48 months

Operational problems of coal-fired power stations

During the combustion of pre-treated biomass with its high contents of chlorine and alkali as well as heavy metals, highly corrosive conditions prevail which place high demands on the installed metal components. The research focus of IFK in this BMWi (Federal Ministry for Economics and Technology) -funded project is the characterization of different pre-treated biomass fuels as well as their evaluation with regard to ash and deposit formation on flue gas side. The DECHEMA Research Institute concentrates on the further development and optimization of suitable coating processes for the protection of the metal surfaces against high-temperature corrosion.

Contact persons: E. Miller, J. Maier

Test Facility: KSVA

Beginning: 01.06.2016, time: 30 months

The VerSi project aims at developing advanced slagging and fouling prediction and monitoring tools for large scale boilers. These include the improvement of the ash deposition on-line monitoring tool, development of the reliable engineering tool as well as development and validation of the CFD sub-models for more comprehensive simulations. The performance of the developed tool will be tested in two reference hard- and brown- coal fired power plant units. The project is funded by BMWi (Federal Ministry for Economics and Technology) and Industrial Partners involved in the project realization.

Contact persons: B. Schopfer, J. Maier

Beginning: 01.08.2015, time: 36 months

The use of biomass and bio-waste in coal-fired power plants is a recognized and important way to achieve the internationally agreed targets for reducing greenhouse gases. In this project on sustainability research with German and Polish partners, methods are to be developed for the pretreatment of biomass for greenhouse gas reduction technologies, in particular for combustion processes with biomass in power generation. The use of waste biomass instead of high quality woody biomass requires pretreatment to reduce adverse effects. The stringy and fibrous nature of the biomass complicates the milling process and co-incineration in existing coal dust mills and combustion systems. Other problems such as slagging and deposits are associated with the significant level of alkali metals in the biomass ash. These limitations require the development of a pre-treatment technique that improves and standardizes the biomass quality, so that it can be used as a substitute fuel for coal.

Contact persons: A. Mack, J. Maier

Test Facilities: KSVA, BTS-VR

Beginning: 10.2016, time: 36 months

DRYLIG is an RFCS project focusing on use of pre-dried lignite for flexibility in power plants. Main scope of the project is the development of new and innovative retrofitting concepts for lignite pre-drying and pre-dried lignite co-firing. The proposed concepts are intended for existing lignite power plant (increase of flexibility, improved operational and environmental performance under low loads), hard coal plants (as start-up/co-firing fuel) and, finally, the enlargement of pre-dried lignite applications in other industrial applications. The research focus of IFK is:

- Milling and drying experiments of low quality lignite containing high moisture and ash content in IFK´s fan beater mill facility

- Small (20 kWth) and large (500 kWth) technical scale co-firing tests of pre-dried lignite & hard coal in different thermal shares to assess emission behavior, slagging and fouling, burnout and fly ash quality.

Bearbeiter: I. Papandreou, J. Maier

Versuchsanlagen: Fan Beater Mill, KSVA, BTS-VR

Projektstart: 01.07.2014, Laufzeit: 36 Monate

In this RFCS EU research project IFK focusses on fireside high temperature corrosion attack against several alloys used in boilers in power plants under different emission regimes and fuels. The inferences should optimise prediction and avoiding of corrosive operation of coal-fired power plants by intelligent Sensing Systems.

Contact persons: P. Winter, J. Maier

Test Facilities: BTS-VR, KSVA, laboratory testing, power plants

Beginning: July 2014, time: 48 months

IIn this German federal research project, IFK investigates the influence of fuel composition and combustion conditions (air, oxy-fuel) on deposit and ash formation and transformation. Moreover, interactions between flue gases, deposits and heat exchanger materials are being evaluated.

Contact persons: R. Spörl, M. Paneru

Test Facilities: KSVA, BTS-VR

Beginning: 01.04.2011, time: 36 months

The BioBoost project concentrates on dry and wet residual biomass and wastes as feedstock for de-central conversion by fast pyrolysis, catalytic pyrolysis and hydrothermal carbonisation to the intermediate energy carriers’ oil, coal or slurry. IFK is performing combustion test of the energy carriers produced from these processes (Bio-Char from pyrolysis and Bio-Coal from hydrothermal carbonisation process). Investigations will focus on the combustion/co-combustion performance and emission behavior. Moreover, fly ash and deposit characteristics regarding slagging fouling and corrosion will be evaluated.

Contact persons: M. Paneru, J. Maier

Test Facilities: BTS-VR, KSVA

Beginning: 01.12.2012, time: 42 months

In the EU FP7 research project, IFK is involved in fuel, flame and combustion characterization and investigations of high temperature gas-side corrosion, flue gas clean-up and the behavior of mercury under oxy-fuel combustion conditions.

Contact persons: M. Escoto de Tejada, J. Maier

Test Facilities: BTS-VR, KSVA

Beginning: 01.12.2011, time: 48 months

The project is administered and technically coordinated by IVD. Major RTD topic is influence of supercritical steam parameters and the combustion atmosphere on the new state-of-the-art evaporator and superheater materials in both conventional air and oxy-fuel firings.

Contact persons: G. Stein-Brzozowska, O. Lemp

Test Facilities: KSVA, laboratory tests, long-time expositions, field measurements in power plants

Beginning: 01.01.2007, time: 4 years

Investigation of the physicochemical procedures during the transformation of the coal minerals and the reduction of fouling and slagging tendencies at the superheater tubes of modern power plants.

Contact person: S. Babat , O. Lemp

Test facilities: KSVA, Power plants

Beginning: 01.01.2009, time: 4 years

Burner development and testing

CEMCAP is an Horizon 2020 project regarding CCS technology development for cement production. IFK’s department Firing Systems is involved in the design, testing and optimization of an oxy-fuel burner as well as in the experimental investigation of entrained flow calcination under oxy-fuel conditions. The Decentralized Energy Conversion department of the IFK is also involved in the project with investigations on the Calcium Looping process.

Contact persons: F. Carrasco, J. Maier

Test Facilities: BTS-VR, KSVA

Beginning: 01.05.2015, time: 48 months

In the EU FP7 research project, IFK is involved in fuel, flame and combustion characterization and investigations of high temperature gas-side corrosion, flue gas clean-up and the behavior of mercury under oxy-fuel combustion conditions.

Contact persons: M. Escoto de Tejada, J. Maier

Test Facilities: BTS-VR, KSVA

Beginning: 01.12.2011, time: 48 months

The project is administered and technically coordinated by IVD. Major RTD topics are combustion tests with different burner set-ups and validation and evaluation of burner set-ups (up to a scale of 30 MW) by using the IFK CFD combustion model AIOLOS.

Contact persons: S. Grathwohl, J. Maier

Test Facilities: KSVA, BTS-VR

Beginning: 01.07.2006, time: 3 years

Contact person: S. Grathwohl, J. Maier

Test facilities: KSVA, BTS-VR

Beginning: 01.01.2009, time: 36 months

Patents and Patent Applications

Contact

Jörg Maier

Dipl.-Ing.Head of Department Firing Systems (KWF)