Plant description

The electrical heated fluidized bed facility “DIVA/ELWIRA” is a flexible plant for the experimental investigation of different combustion, gasification and CO2 capture technologies.

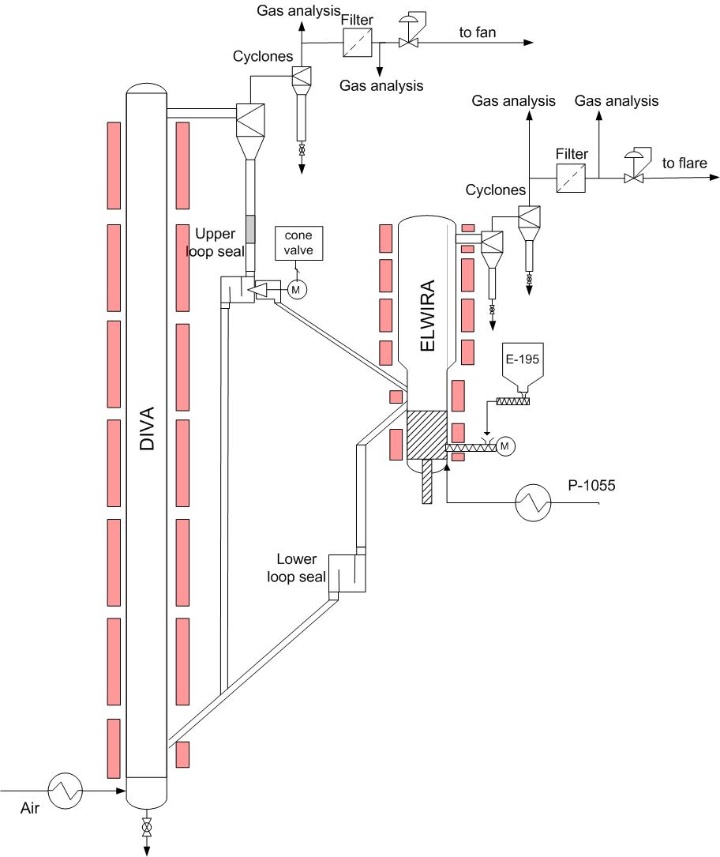

Due to the constant exchange of bed material between the two fluidized bed reactors, in particular dual fluidized bed processes such as steam gasification, chemical looping or calcium looping can be investigated in a continuous operation.

Besides the dual fluidized bed operation, the operation of a single reactor, e.g. for combustion experiments (emission measurement, fuel characterization, agglomeration behaviour…) is also possible.

Plant data

| ELWIRA | DIVA | |

| Regime | Bubbling fluidized bed | Circulating fluidized bed |

| Fluidization velicity | 0,2 – 1 m/s | 4-6 m/s |

| Diameter | 150 mm | 70 mm |

| Reactor height | 3,5 m | 12,4 m |

| Temperature | Up to 950 °C | Up to 900 °C |

| Fuel dosing | Volumetric dosing of solid fuels, gaseous fuels | Gaseous fuels |

With the fuel feeding system, different solid fuels such as coal, biomass and residues as well as additives and sorbents can be dosed.

Pressures and temperatures are continuously measured at multiple locations. At the ELWIRA plant, the gas composition can be measured at the end of the reactor, after the secondary cyclone and after the candle filter. At the DIVA plant the gas composition can be measured after the secondary cyclone and after the candle filter. The following gas components can be measured:

| Combustion gases | Gasification gases | |

| Online measurement | O2, CO2, CO, SO2, NO, NO2, N2O, (HCl) | O2, CO, CO2, H2, CH4, C2-C4 |

| Wet chemical measurement | HCl | Tar concentration, H2S, NH3, HCl |

Other measurements on request.

The following sketch shows a simplified schematic of the plant:

The temperature of the whole plant is controlled flexibly by an electric system. Therefore, nearly any temperature profile can be simulated.

At the upper loop-seal of the DIVA plant, the solid flow to the ELWIRA plant can be controlled by the opening of a cone-valve. The backflow to the DIVA plant is controlled by an overflow.

Contact

Jörg Maier

Dipl.-Ing.Head of Department Firing Systems (KWF)